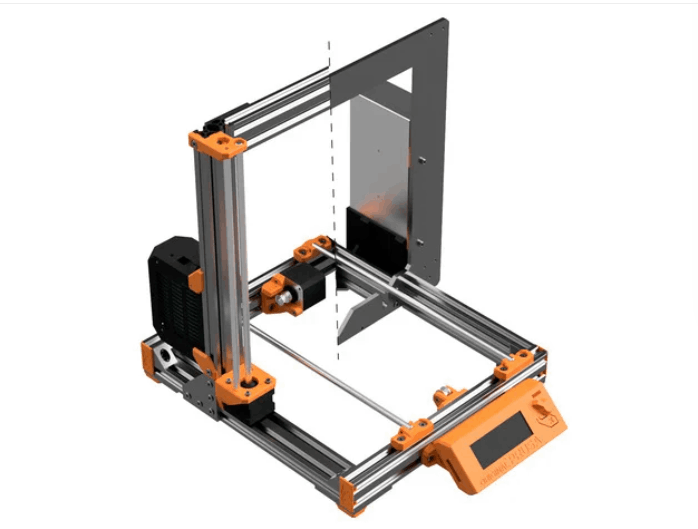

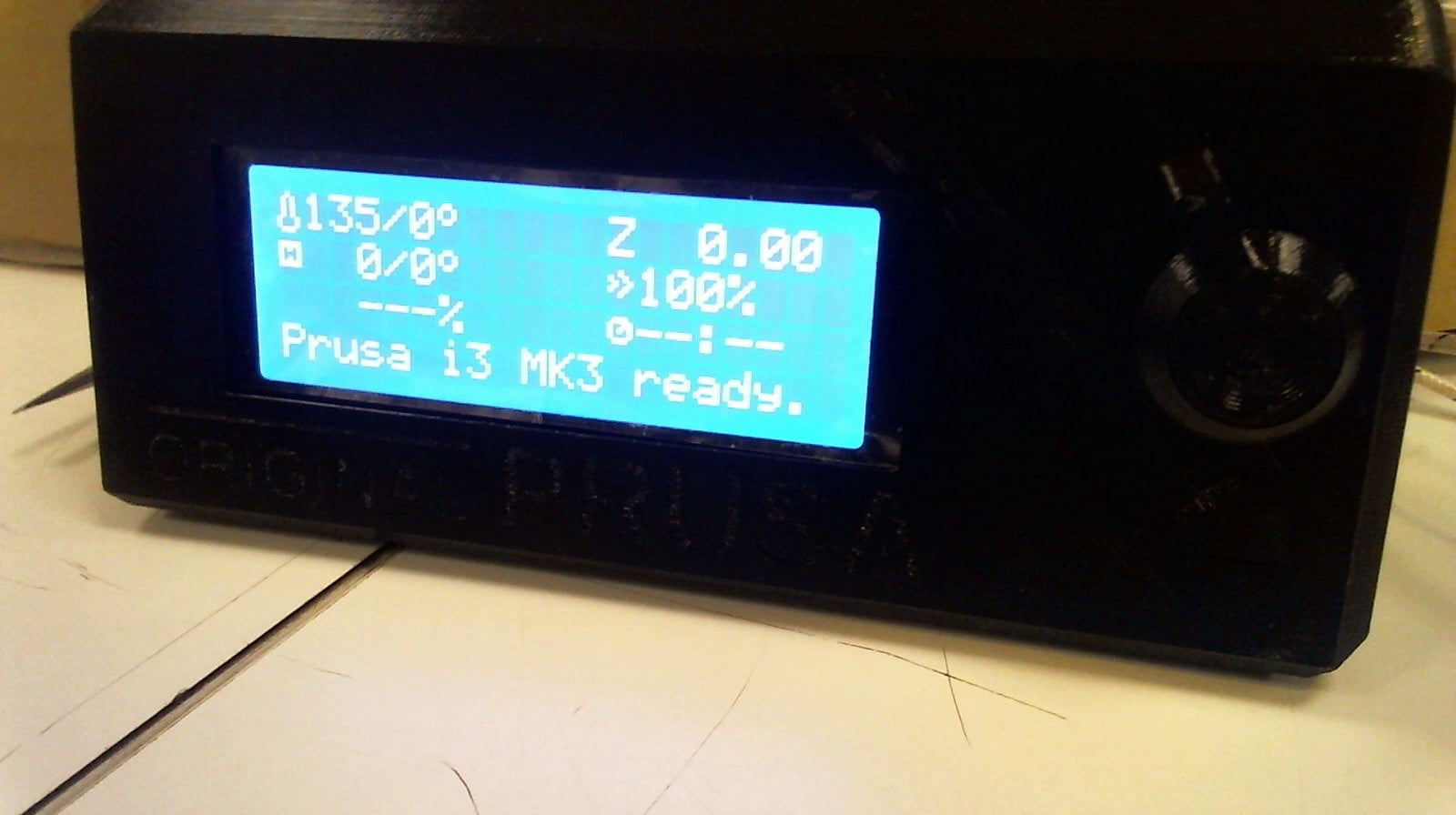

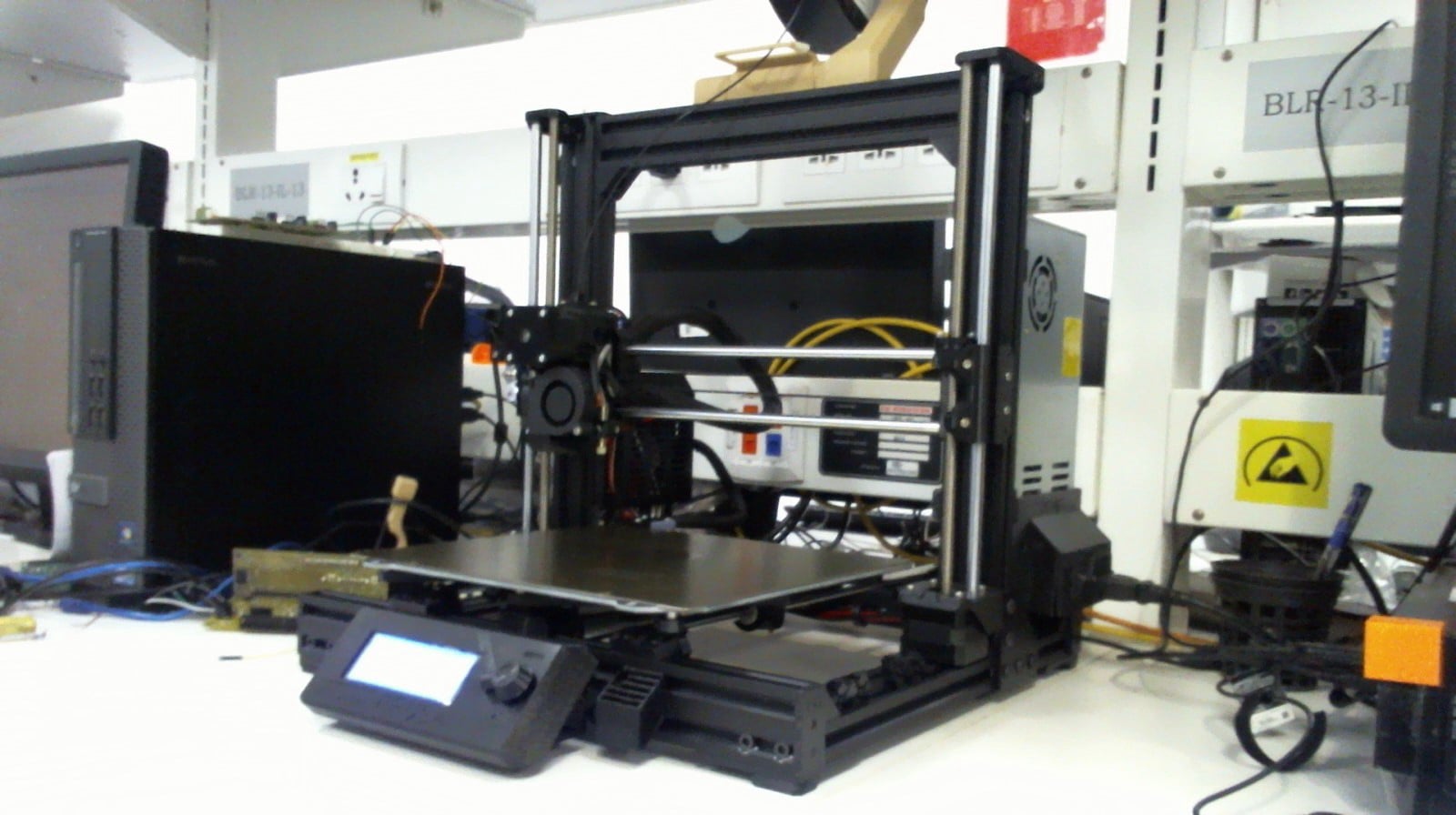

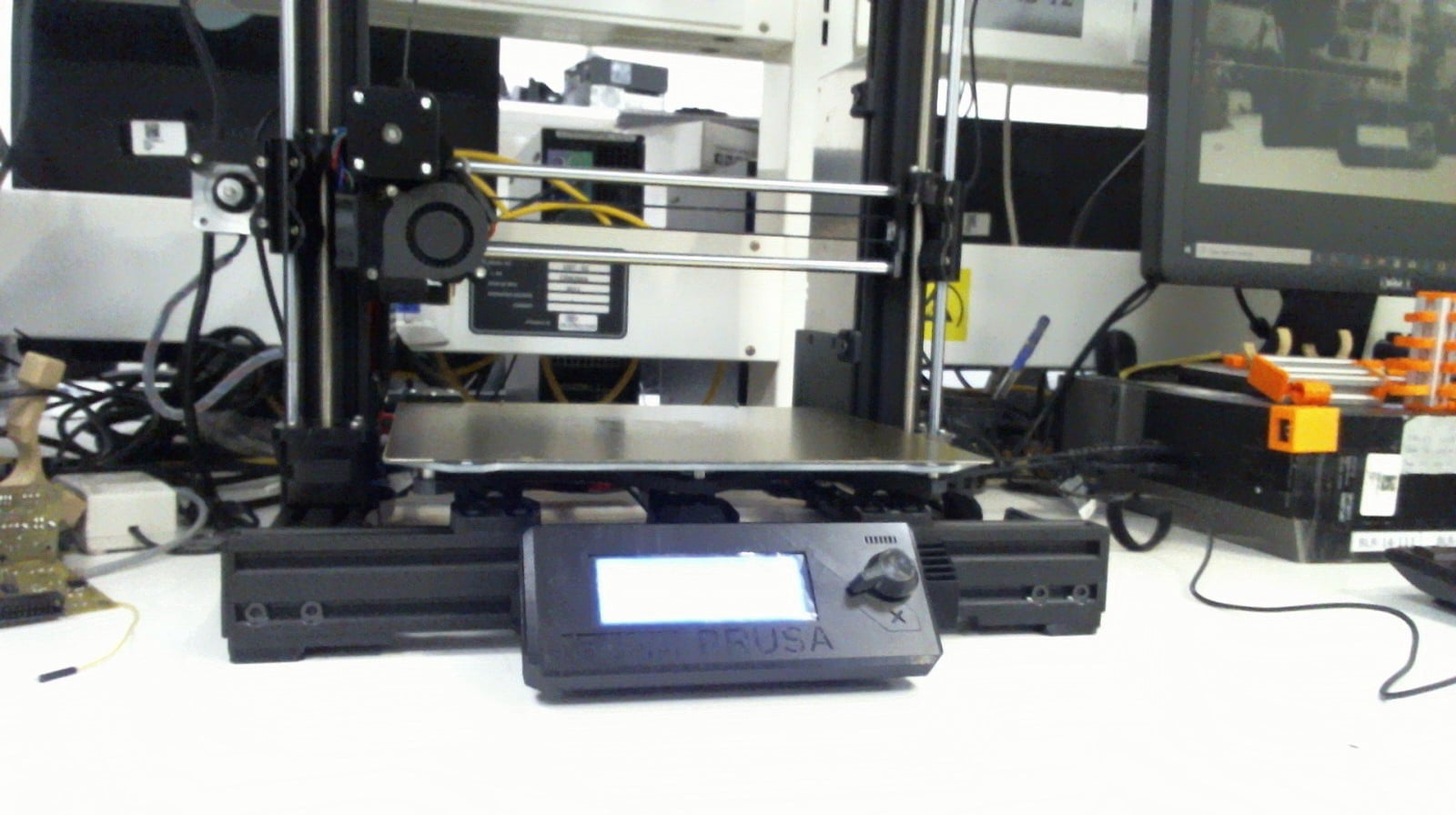

Customised and Reverse-Engineered Open Source 3D Printer - Prusa i3 MK3 (Bear Upgrade)

How it started?

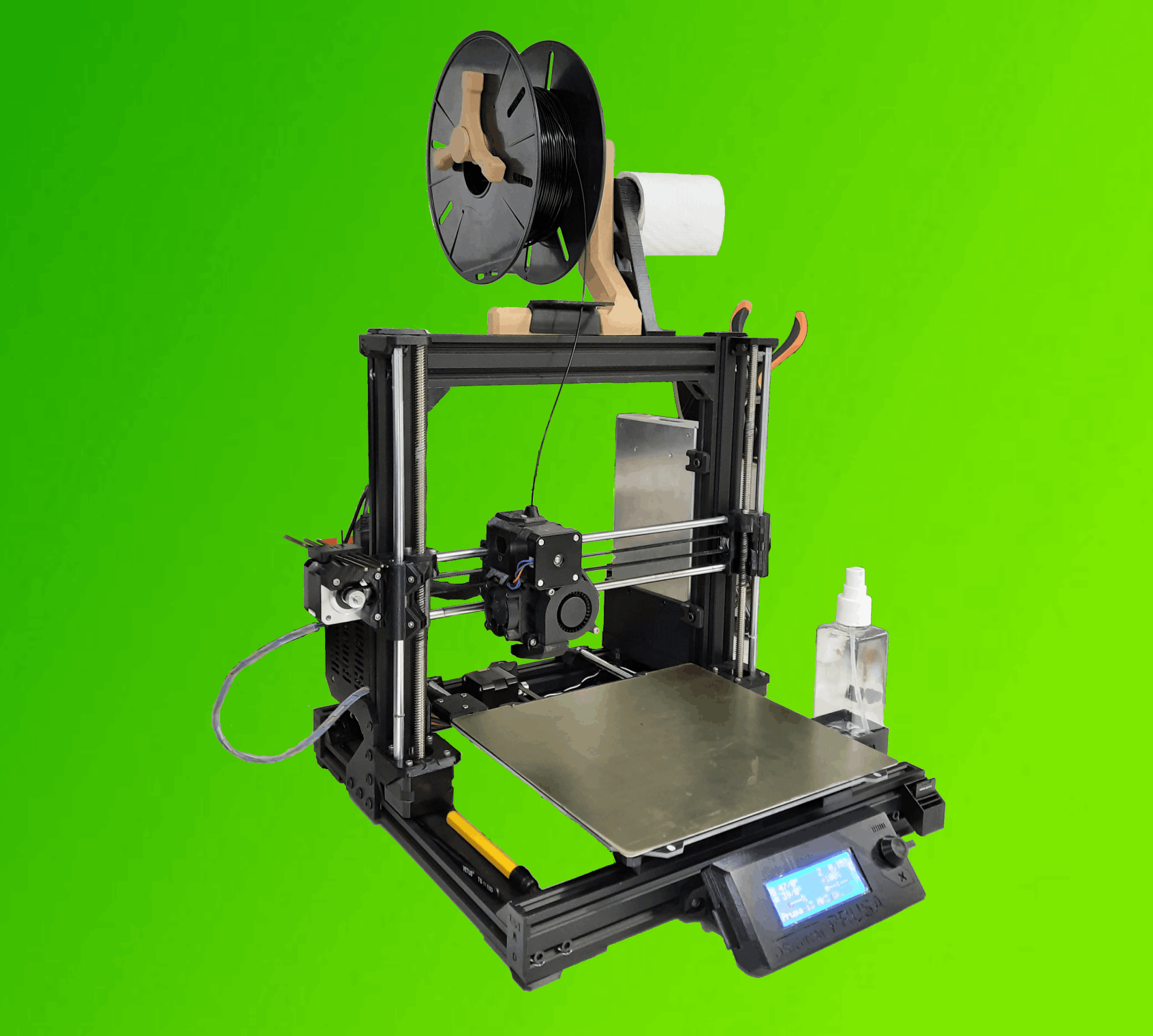

The Prusa i3 MK3, renowned by 3D Printing enthusiasts as the pinnacle of desktop 3D printers, holds a special place in the world of additive manufacturing. Its distinction lies in being an open-source marvel, a testament to collaborative innovation. Within this dynamic landscape, an individual named Greg, who is easily accessible on GitHub, undertook a transformative journey. Greg's vision culminated in what is now celebrated as the "Prusa i3 MK3s Bear Upgrade."

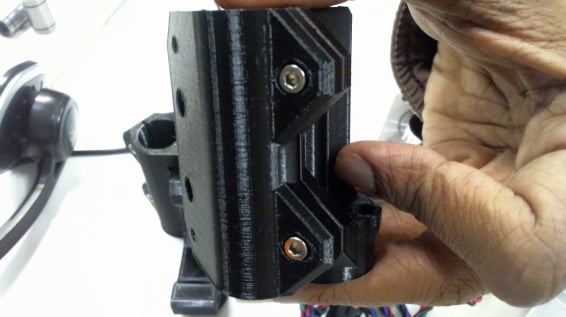

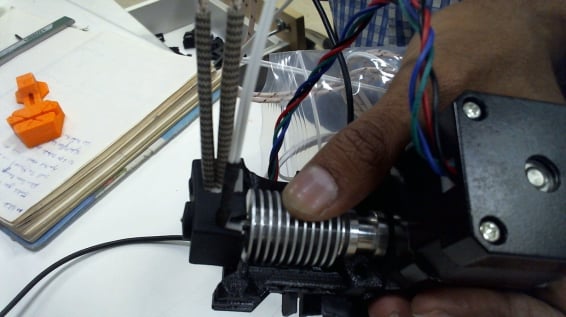

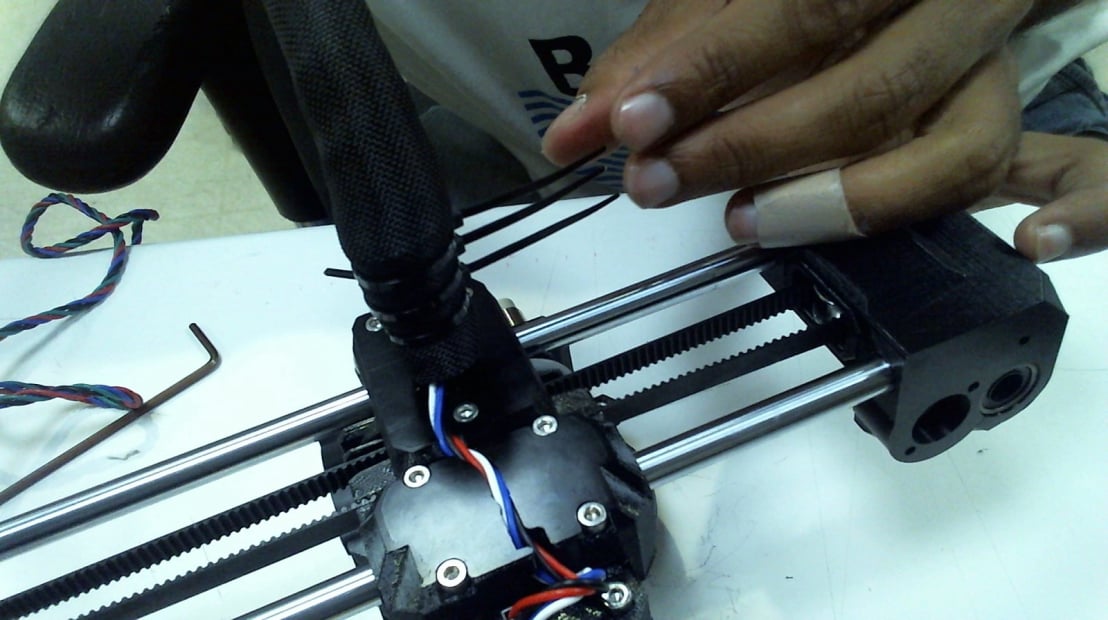

Reverse Engineering Meets Customization: A Unique Endeavor

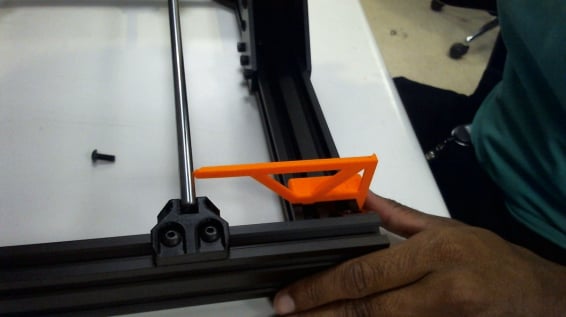

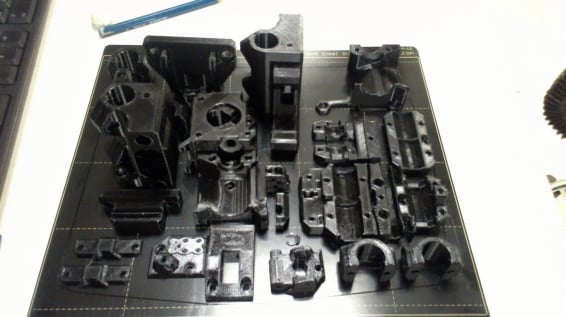

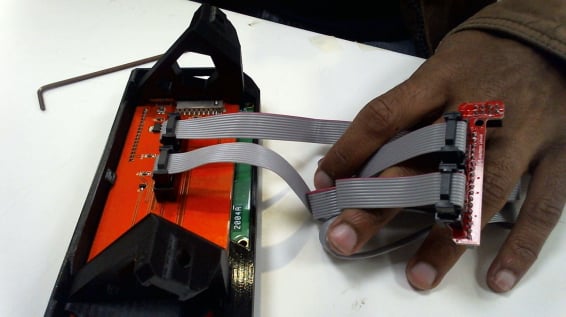

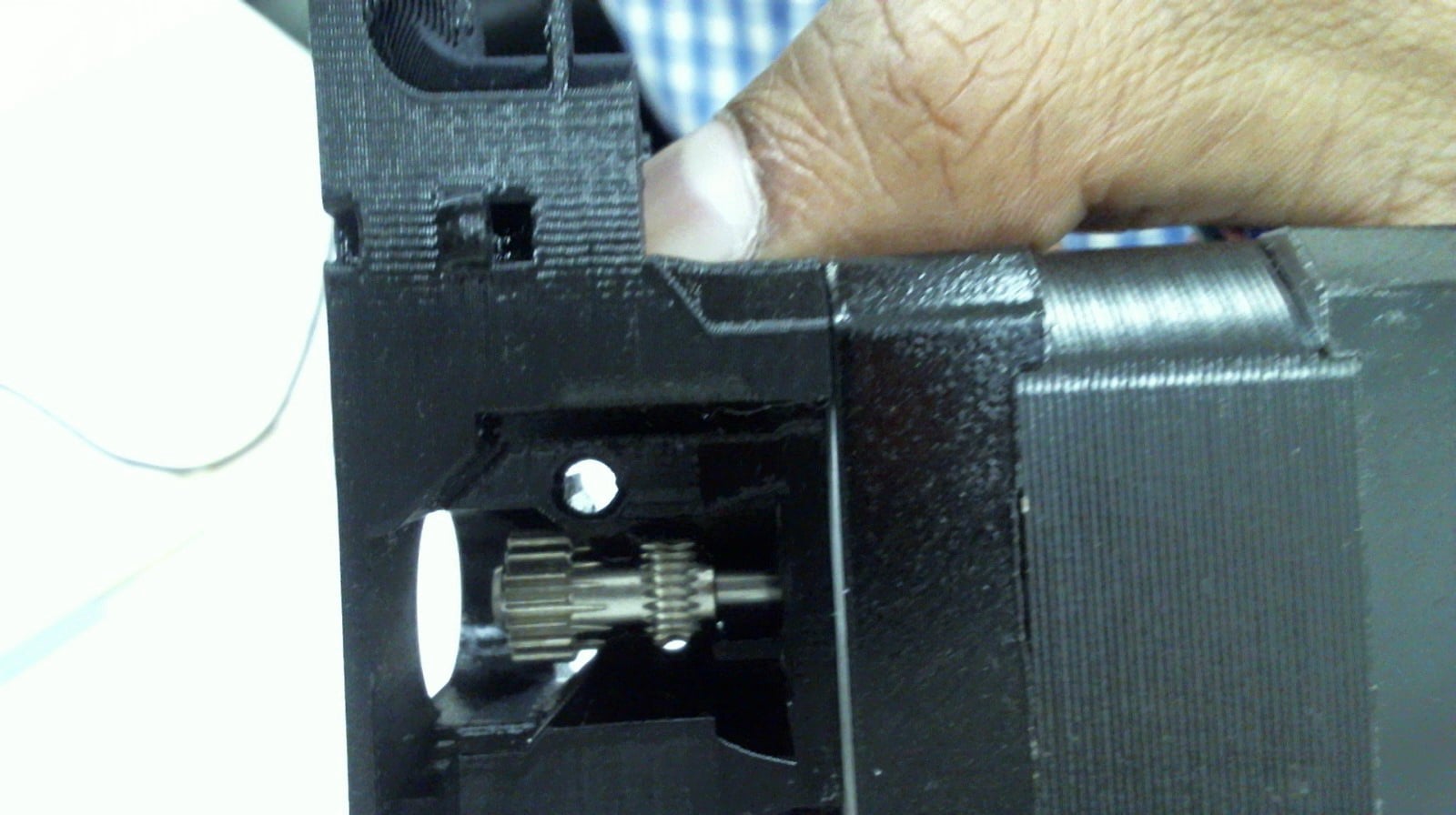

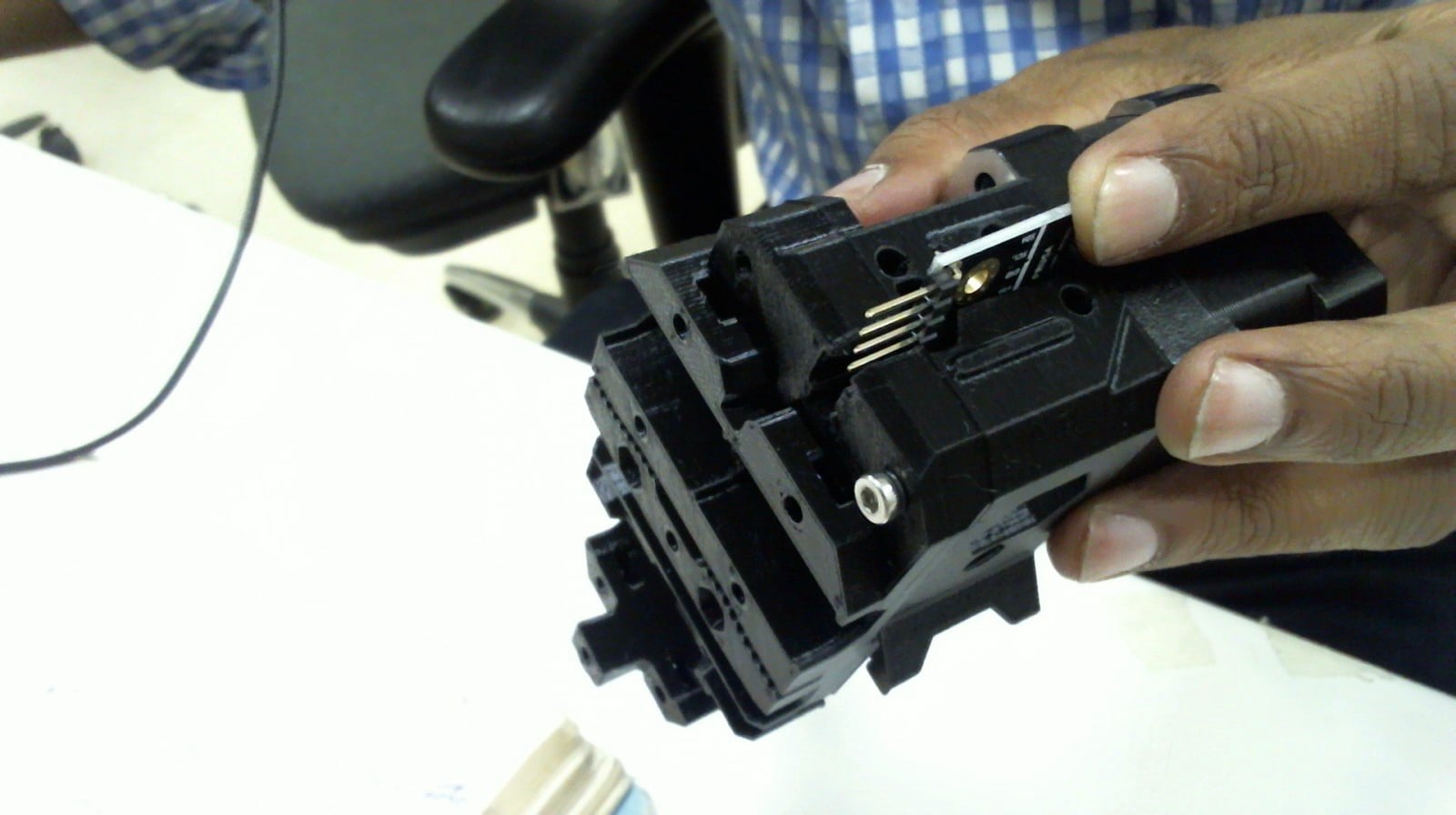

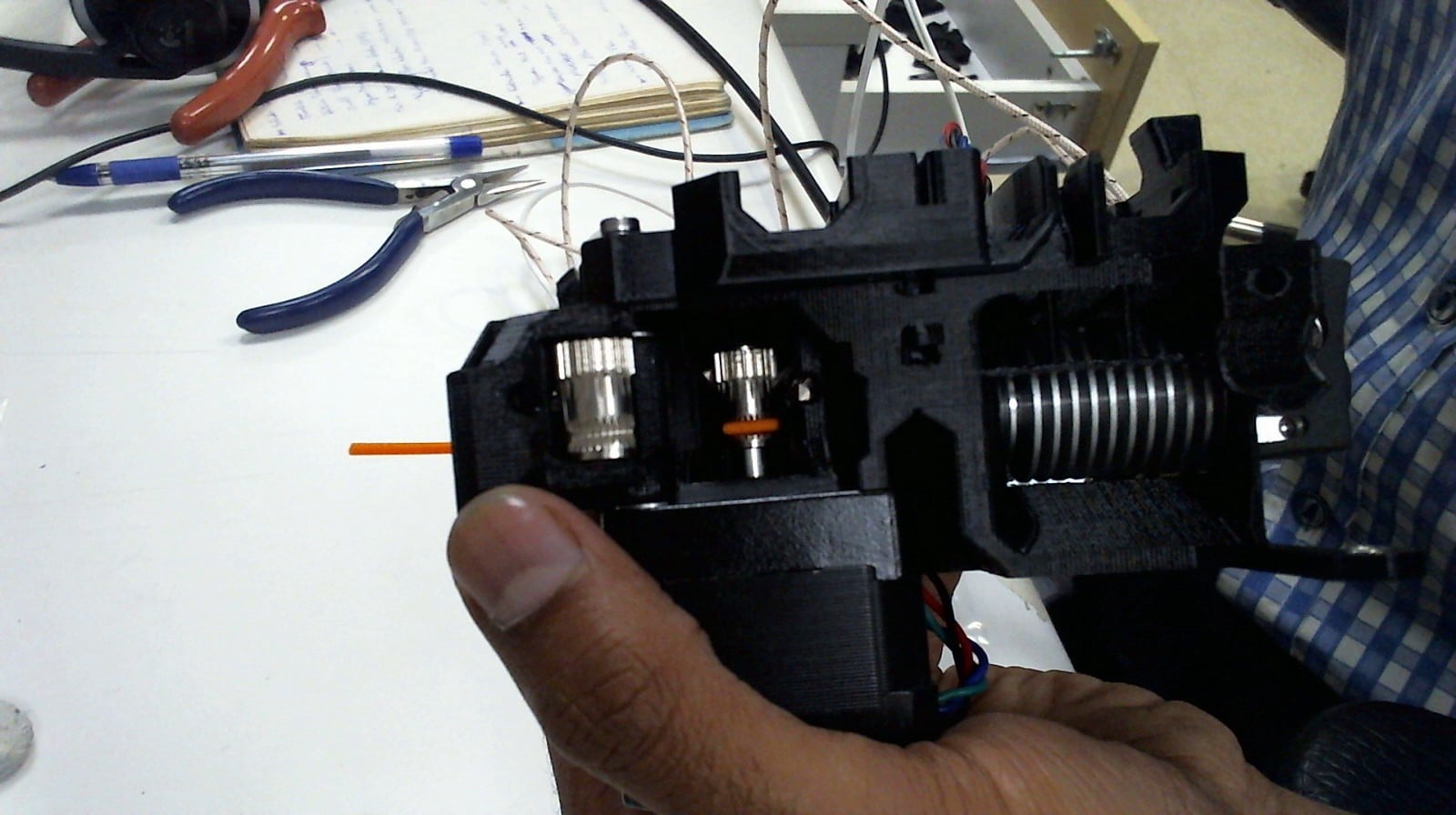

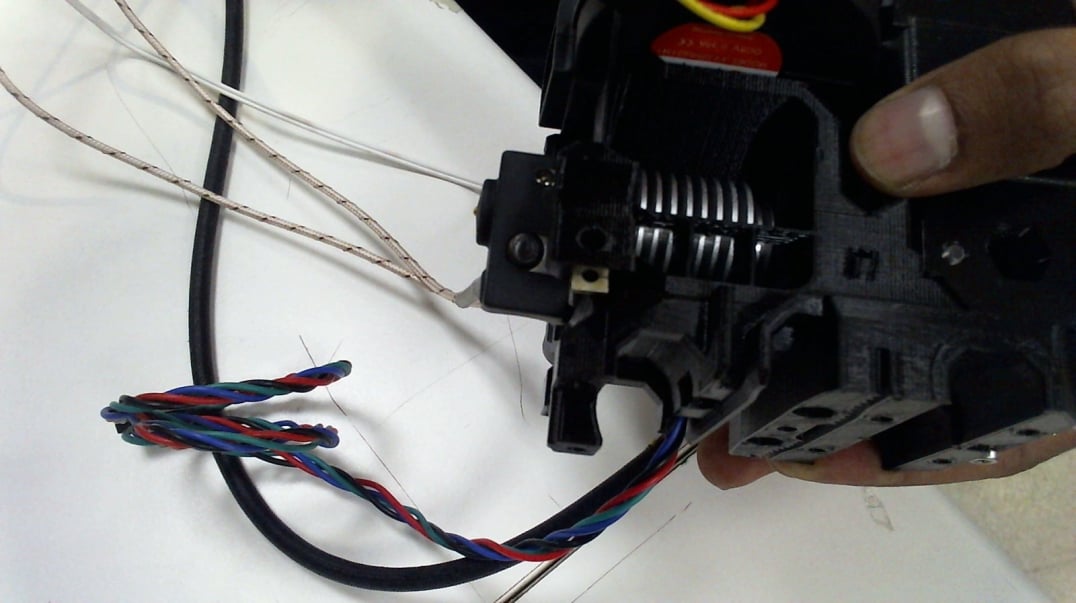

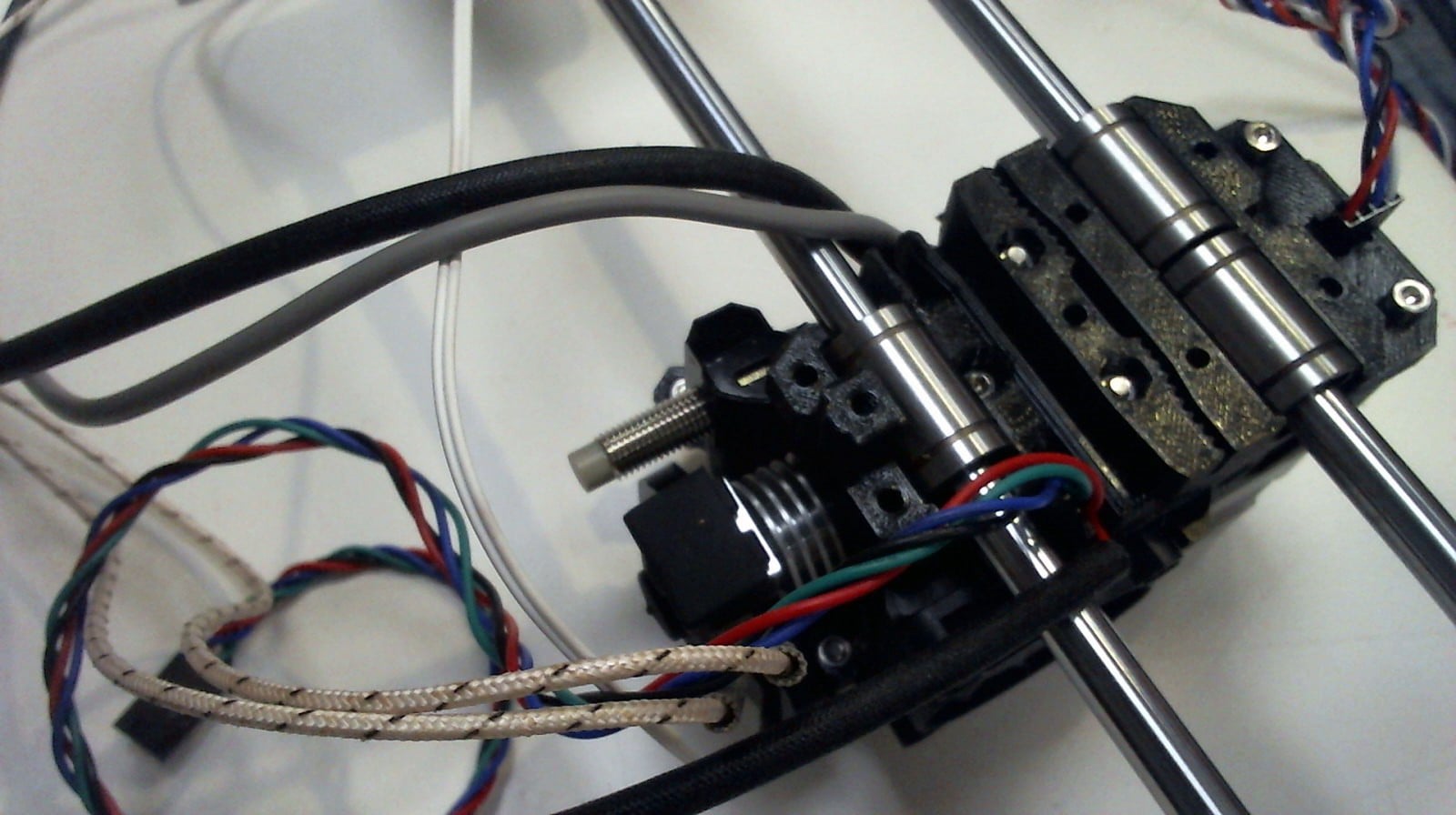

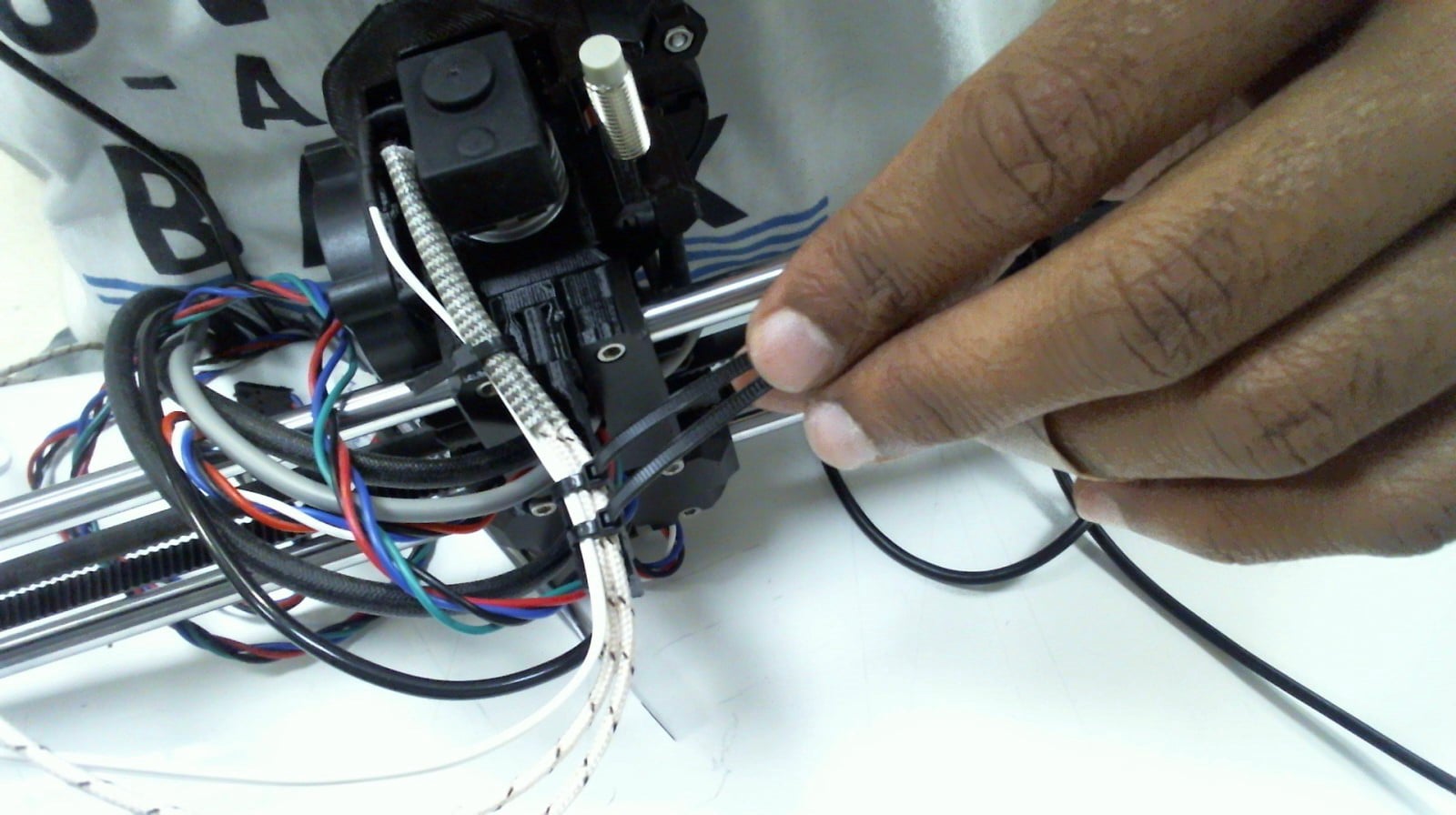

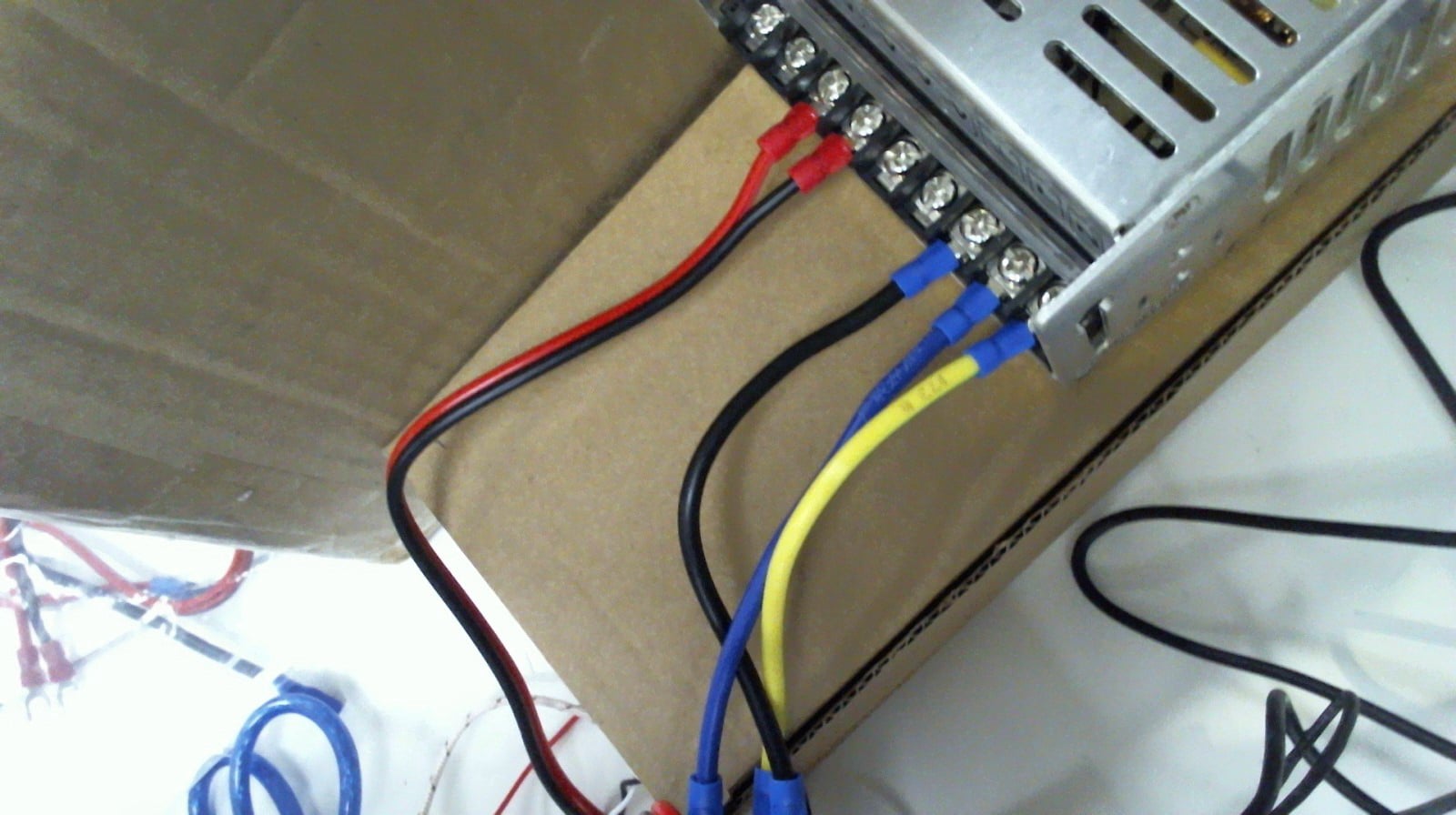

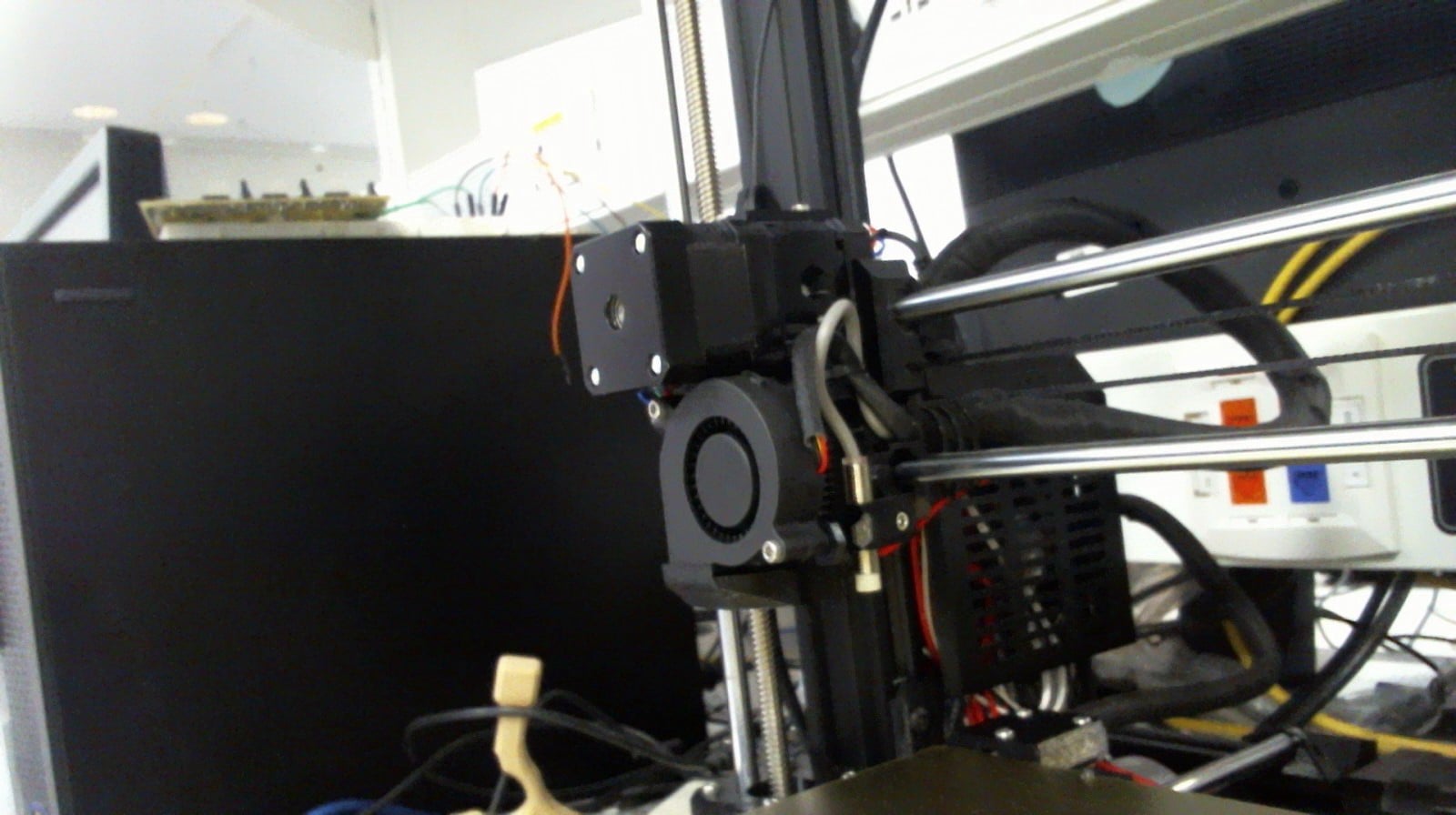

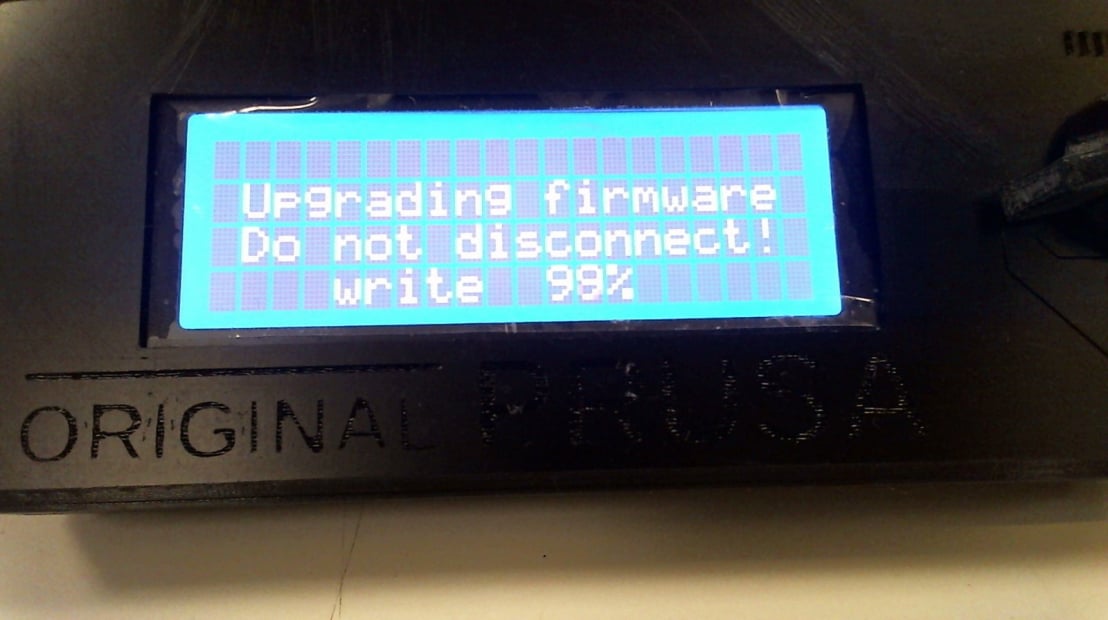

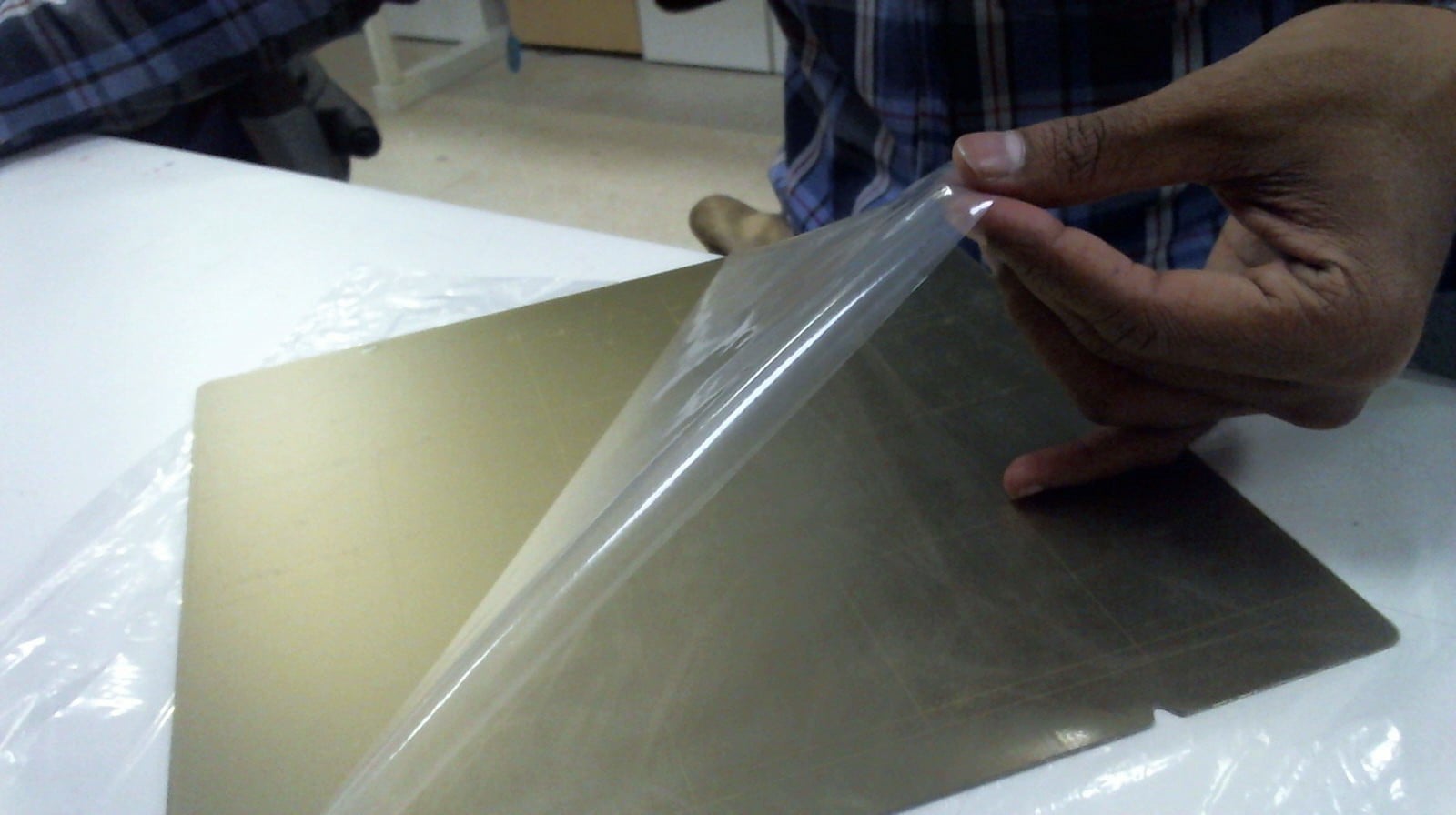

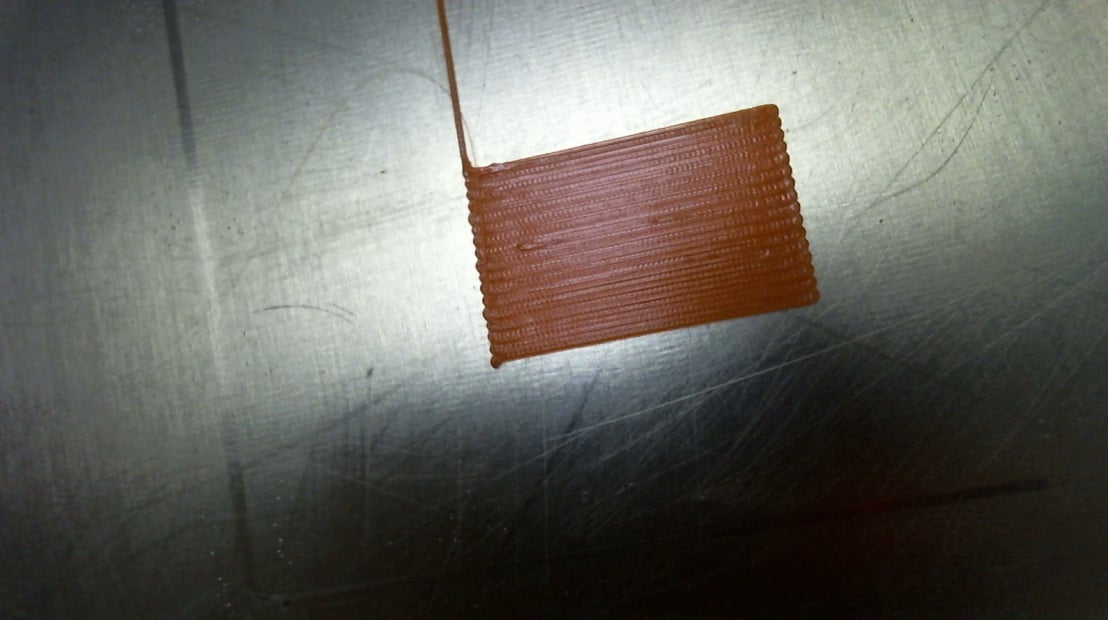

What truly sets this project apart is its foundation in reverse engineering. It's a process where we dismantle and decipher the inner workings of the Prusa i3 MK3, with the goal of not only understanding but also enhancing its capabilities. Greg's Bear Upgrade is the embodiment of this philosophy. And I, as an enthusiast and a learner, eagerly took on the challenge.

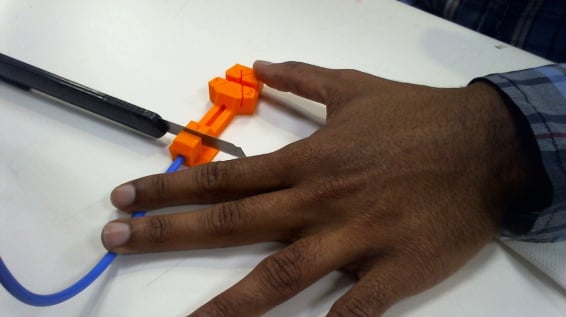

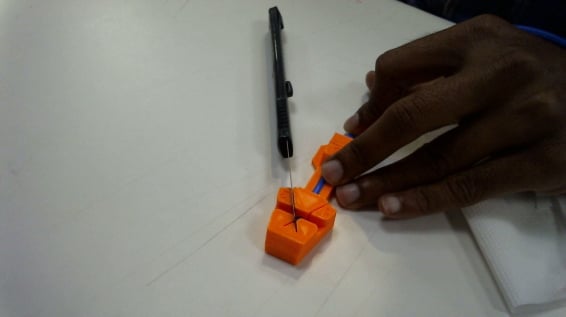

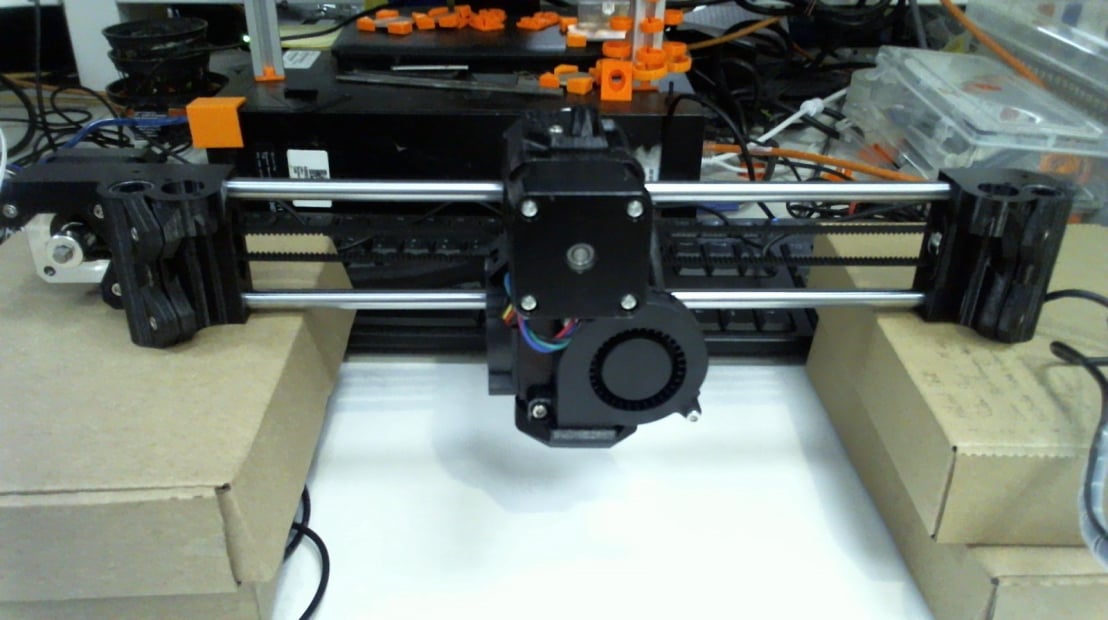

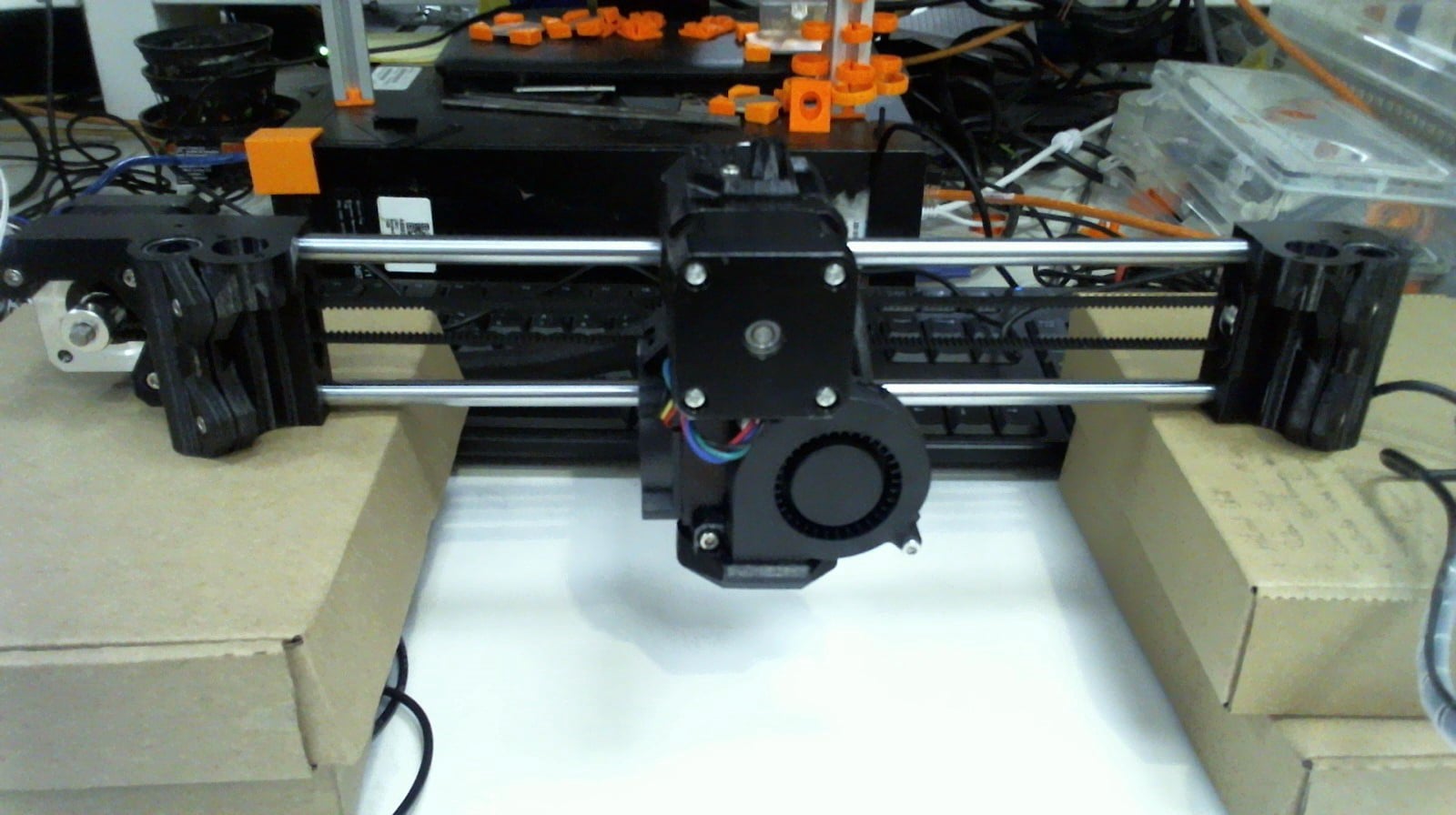

Learning through Hands-on Innovation

My journey began by immersing myself in the intricacies of the Prusa i3 MK3 and the ingenious upgrades introduced by Greg. It's an educational experience that goes beyond traditional learning. It's about practical application and the joy of discovery. By learning from the open-source community and putting that knowledge into practice, I've gained an in-depth understanding of 3D printing technology.

In essence, this project represents more than just a technical endeavor. It symbolizes the spirit of collaboration and innovation within the open-source 3D printing community. It's a journey of reverse engineering, customization, and the continuous quest to push the boundaries of what's possible with the Prusa i3 MK3.