Sequential Processing Hexagonal Reactor (SPHERE) for Bio-degradable Hospital Waste.

How it started?

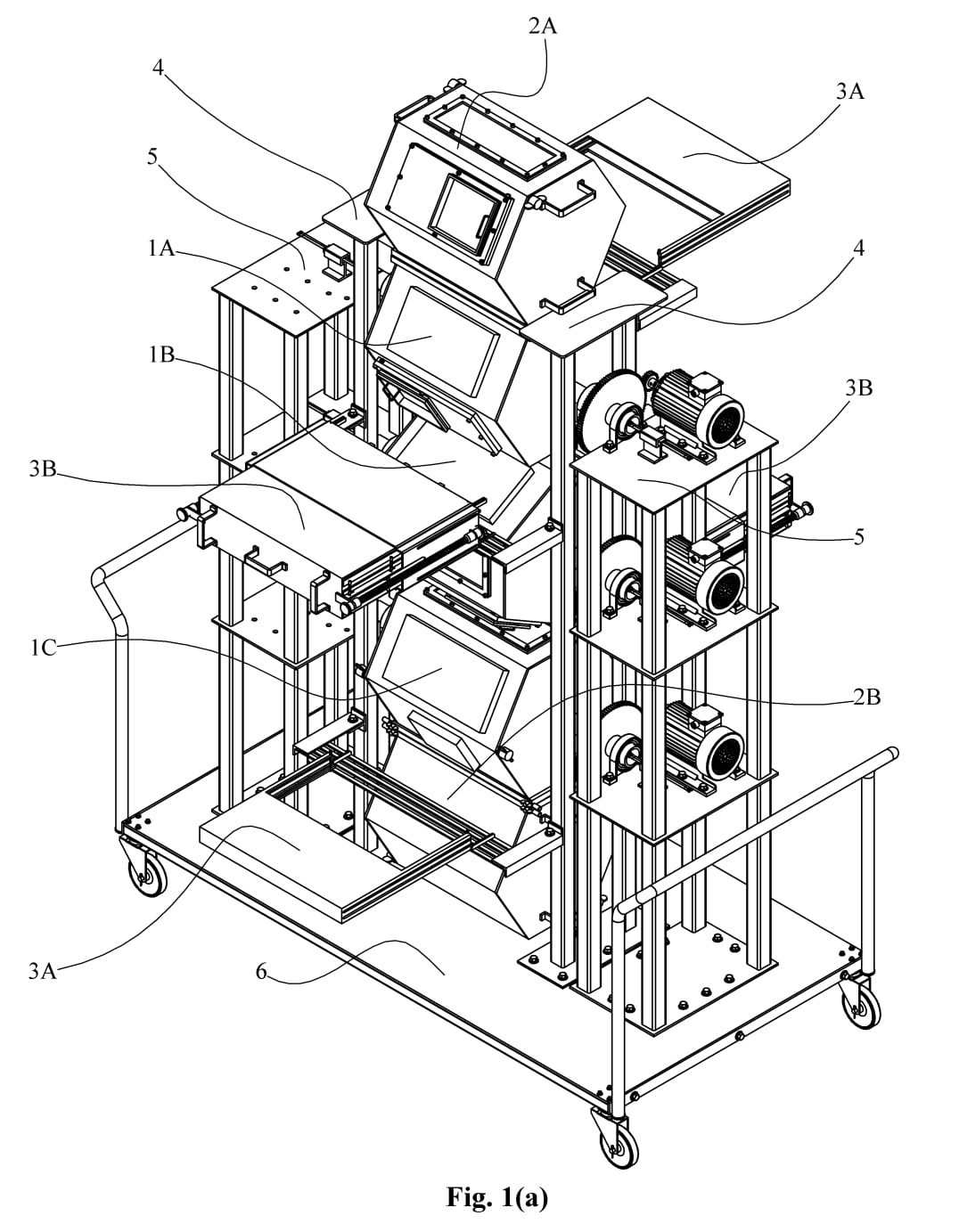

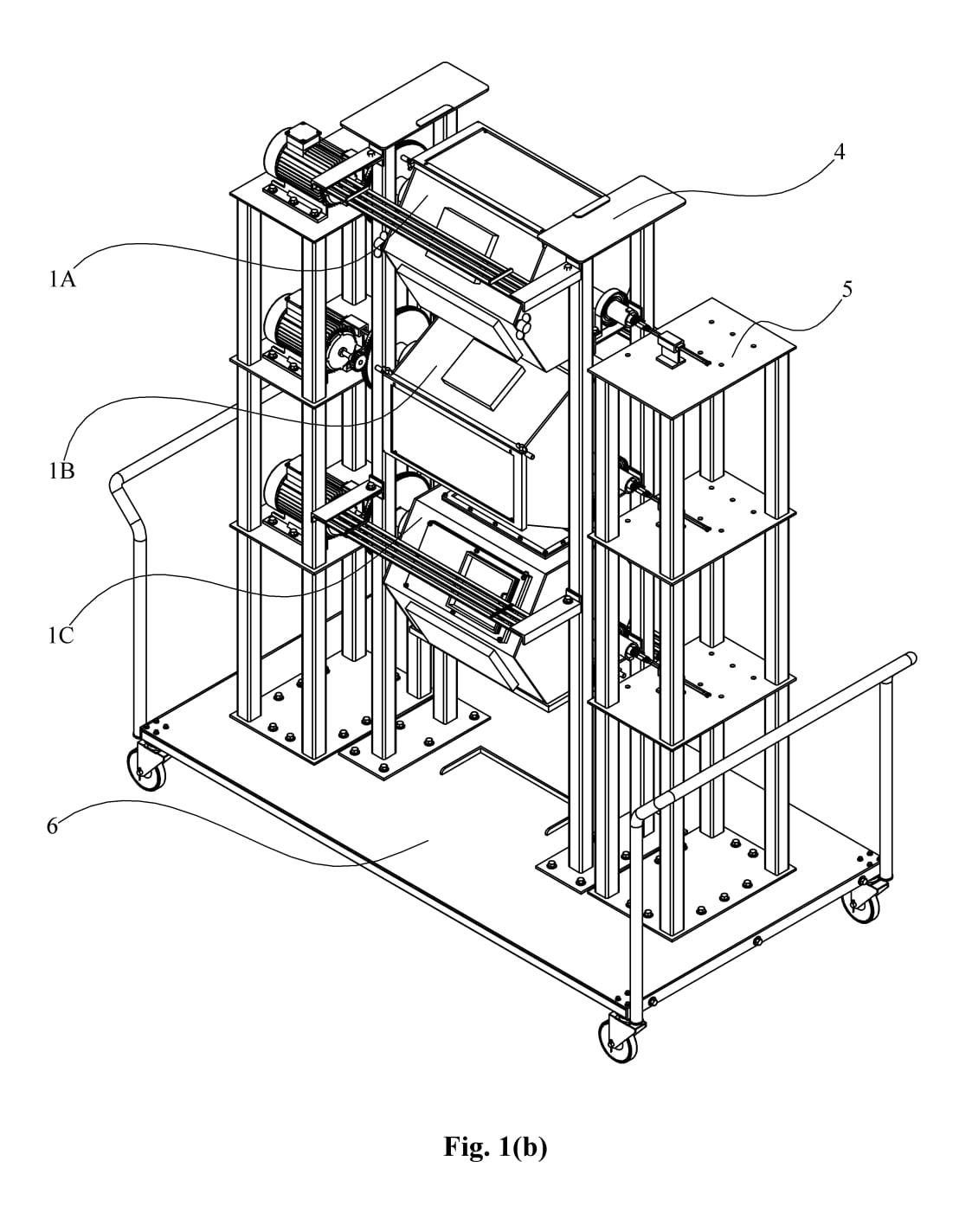

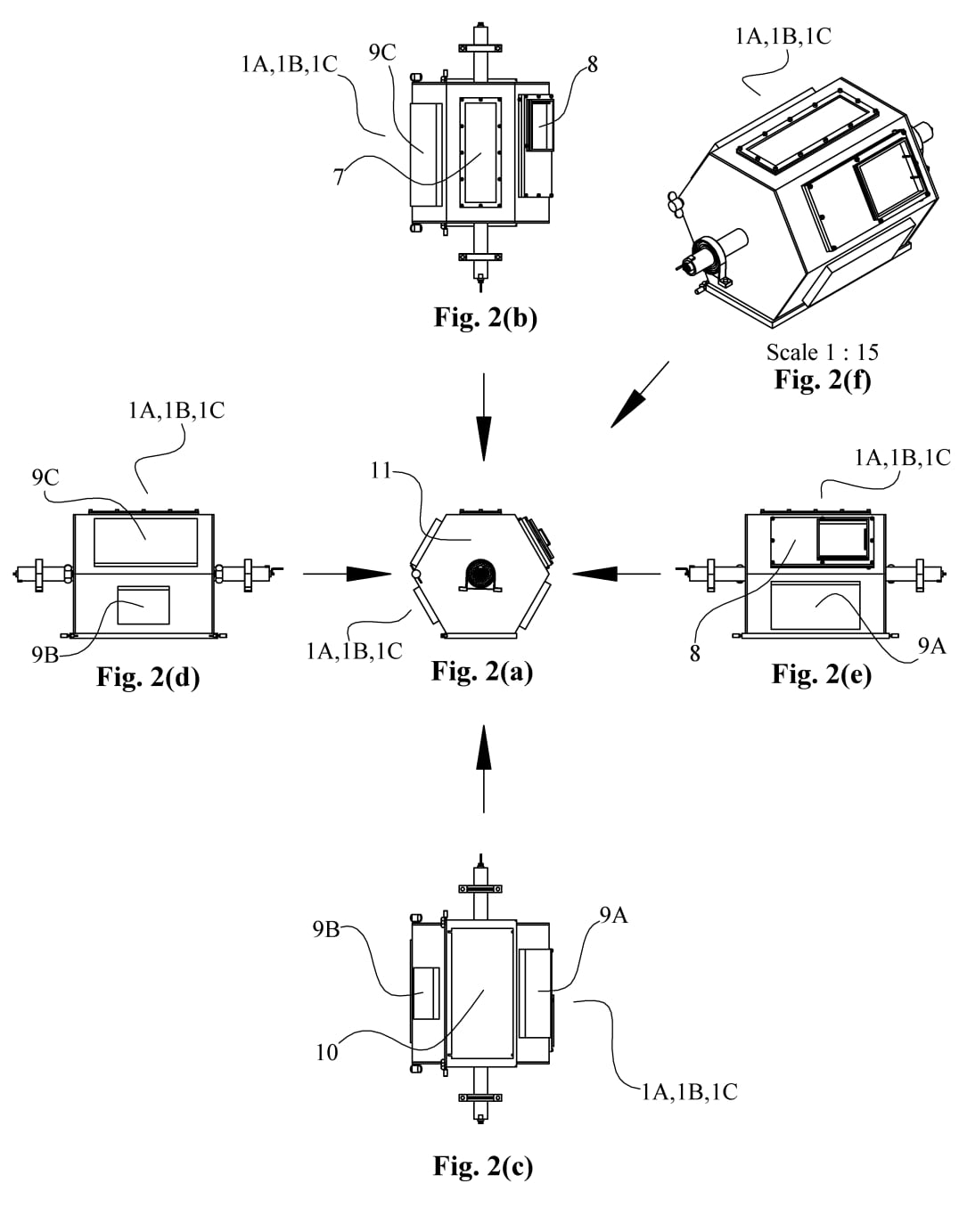

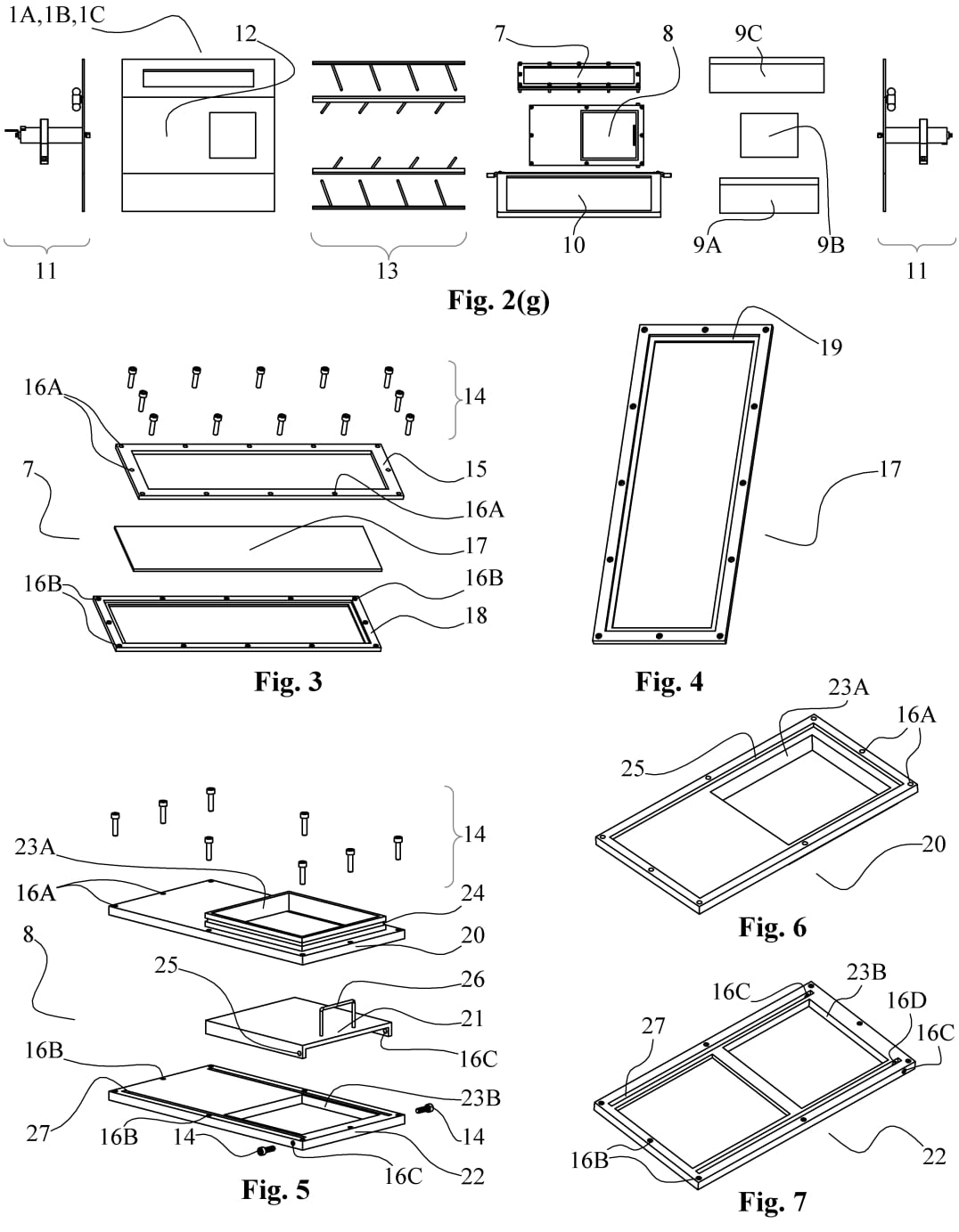

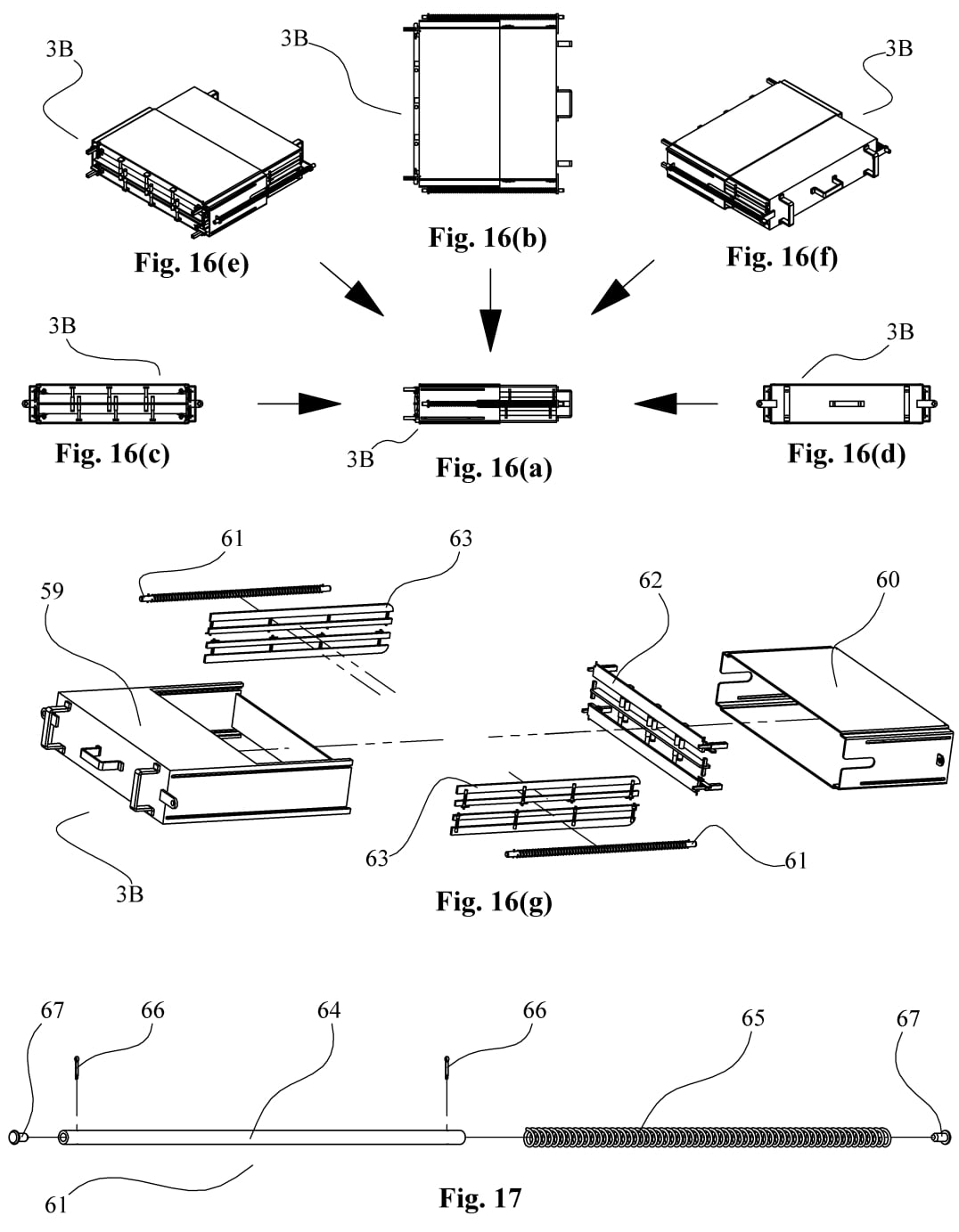

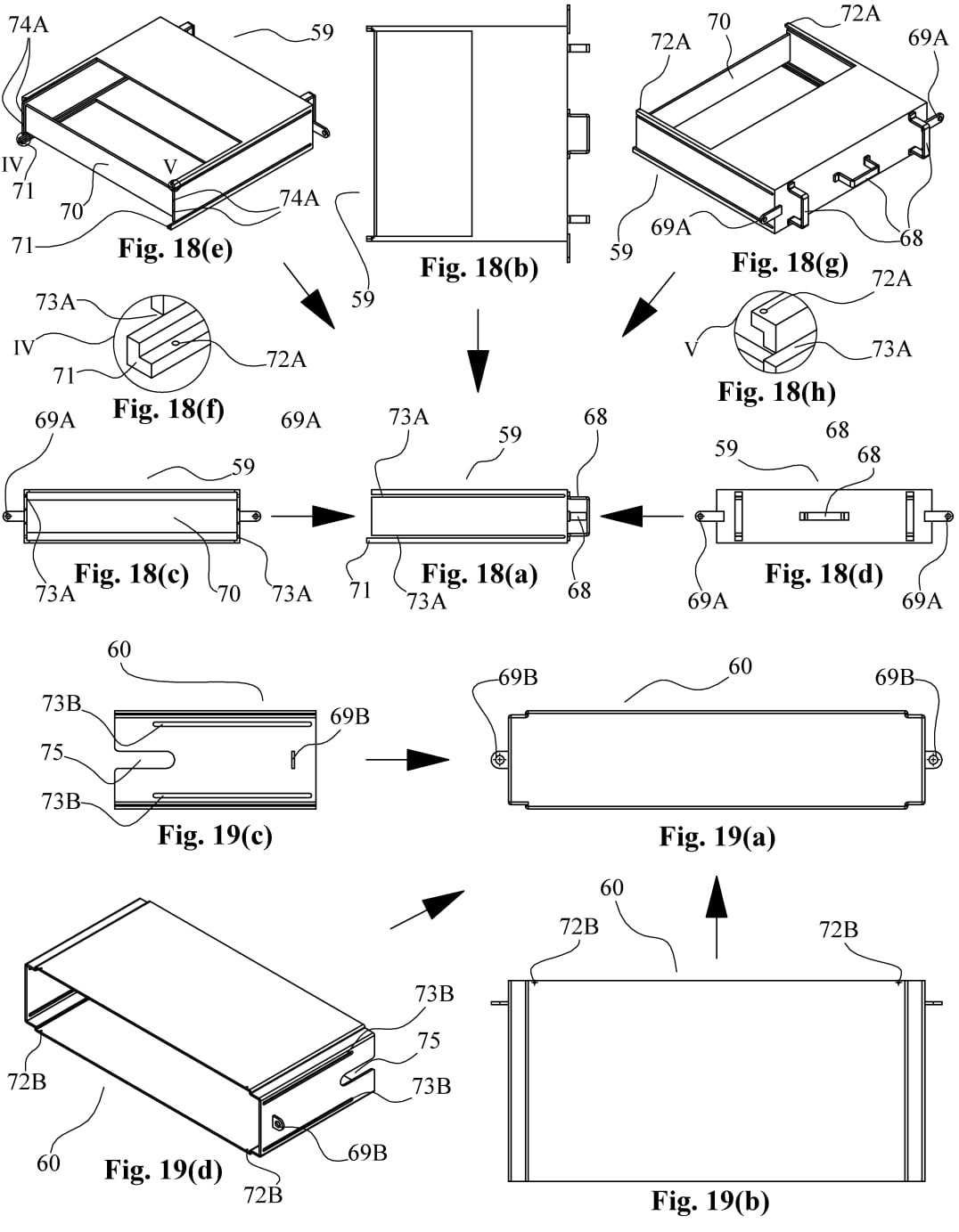

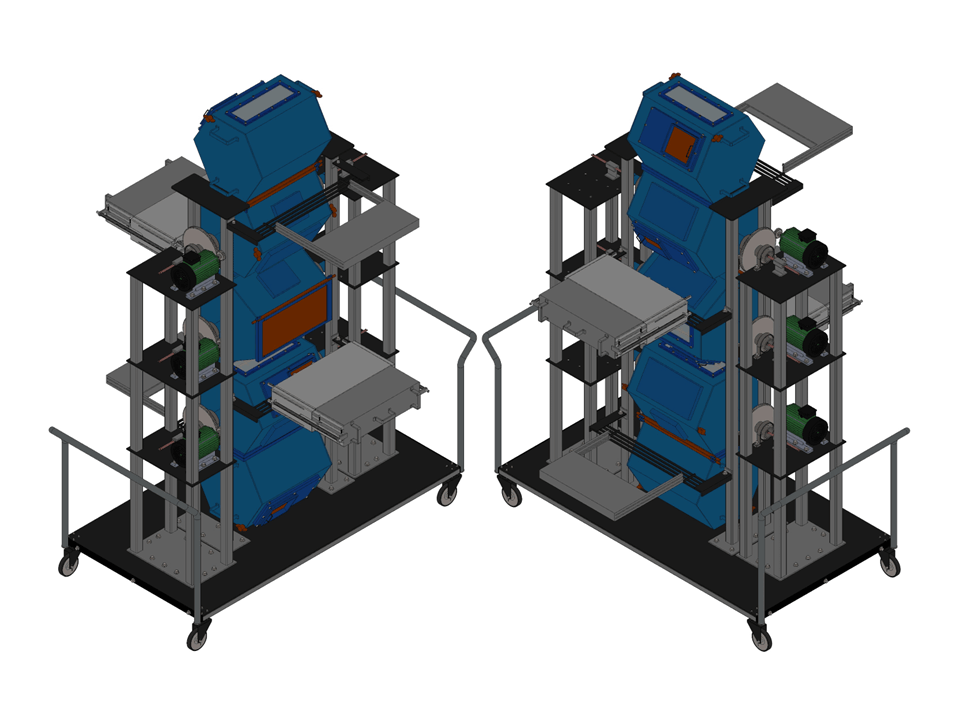

During my time at PMIST, I had the opportunity to work closely with Dr. S. Kumaran, a distinguished Biotech scientist and the Dean of Research. He presented me with a challenging task: to create a machine capable of processing bio-medical waste, specifically Human Anatomical Waste, within a closed container. The machine needed to incorporate several essential features, including a stirrer, spray nozzle, see-through glass, sample collection port, drain/gas vent, and transfer port. Notably, the design had to maintain a closed environment and exclude any electrical interfaces.

To address the problem effectively, I devised a sequential process involving microbial, chemical, and nano-particle treatments. The goal was to achieve harmless residue as the end result of the waste processing. With this ambitious project brief in hand, I began the design process on paper and diligently worked towards a viable solution.

After an entire year of dedicated effort, the project finally took shape and proved to be a potential candidate for patent protection. Although my involvement in this endeavor was entirely voluntary, I found immense satisfaction in contributing to such a meaningful initiative. Throughout the project, Dr. Kumaran provided invaluable guidance and unwavering support, which played a crucial role in its successful development.

The outcome of this collaborative effort showcases not only the power of scientific innovation but also the importance of mentorship and teamwork in driving real-world solutions for pressing challenges.